![]() Further reports:

Further reports:

Summer 2023

Winter 2022/23: Working on the turret

Winter 2021/22 and summer 2022: Working on the turret

Winter 2020/21 and summer 2021: The electrical system and hull

Winter 2019/20 and summer 2020: Turret and the electrical system

Work on turret and the electrical system

Due to the extraordinary circumstances this year we cover both seasons in one report.

During the last year work revolved mainly around completing the turret with interior and gun. In addition we have made a new wiring harness for the hull.

We inserted the gun cradle and the rear barrel section with breech block through the rear turret hatch by lifting it with our roof crane and pushing it inside the turret as far as possible. Subsequently we pulled both parts further forward along a wooden plank with a steel rope through the turret front opening resp. the cradle with a winch.

Even though the act took longer than writing these lines it proceeded rather smoothly given that we have never done that before.

Back in the days of the Tiger within the course of the turret assembly the cradle will probably have been moved under the turret on a mobile device and been pushed forward. Unfortunately our turret frame didn’t permit that.

Pushing the gun shield with its over 800 kg as smooth as possible over the rear section of the cradle required a horizontal alignment. We achieved that by lifting the front of the cradle with a hoist.

It is not visible on the photos but the number of photographers in times exceeded the number of workers. After a previous newspaper report about our work a local TV station became aware of Uwe of our team and took the chance to film him for a TV special during his hobby work.

Eventually due to his stature Uwe was the only one who could handle a 20 kg hammer overhead to drive the shield forward mm by mm over the last centimeters.

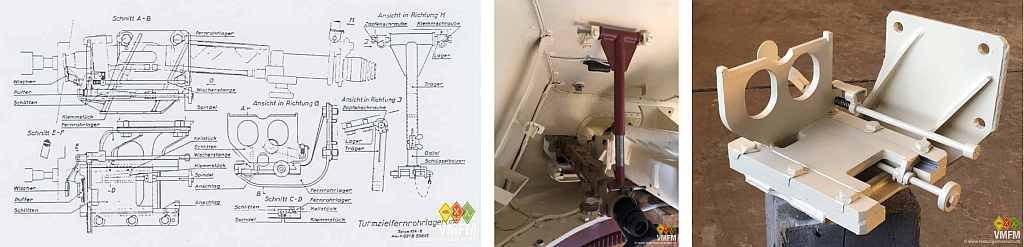

A major job, equally tedious and demanding in all its details, was the recreation of the bracket which holds the gun sight and attaches to the gun cradle.

Starting in April 1944 the previously used binocular gun sight TZF 9 b/1 was replaced in the King Tiger by a monocular version TZF 9 d. Nonetheless, the mounting bracket with two openings for the parallel lenses continued to be used.

The front bracket is a kind of slay which can be moved forward and backward in two adjustable sliding bars on a large tray which is attached directly to the gun cradle. The rear of the gun sight is held by an adjustable rod which is attached to the roof. All three parts were missing in our Tiger. We received the tray and rear rod as reproductions of originals but had to make the bracket ourselves.

We could find a technical drawing of this bracket but no picture of an original, not to speak of a survivor. Based on what we got we made a stencil and modified it step by step until it fit.

Only one detail remains unclear: The lower hand wheel applies a fixation mechanism which we could not figure out in detail from the technical drawing. We discussed leaving he hand wheel without function or improvising a mechanism, and eventually opted for the latter.

The result is a pleasure to the eye and a new masterpiece of Björn.

Several plans exist for the reconstruction of the wiring. They are not all original from the King Tiger. But also plans of the Panther wiring along with the remainders of our main harness and many photos helped to re-create the entire system.

The biggest problem were the textile hoses which the majority of the wires were running in. These hoses consist of a light beige cloth with a texture similar to linen. The cloth was used with various diameters for the different wire lines and was covered with a transparent varnish which made them stiff. In the turret they were ultimately sprayed with the inner turret paint.

Today cloth is replaced by plastic braids and the originals could not be tracked anymore.

The cloth covered harnesses are:

- The main line with 11 cables from the driver’s control board along the hull floor up to the fire wall. On the firewall it splits up into individual covered lines.

- A parallel line with two wires to the firewall and further to the magnetos.

- A line starting at the Kasten 5 C on the turret platform support along the lower turret hull and the left side turret wall up to the turret roof, where it splits into lines running to different directions along the turret roof.

We made the covers for the large strings from cloth which resembles linen. After cutting it in stripes we cemented them to a hose by wrapping it around a rod with the respective diameter.

The very small diameters for one or two wires could hardly be cemented and we picked plastic hoses. Inside the turret the harnesses will be painted anyway so that the difference is not noticeable.

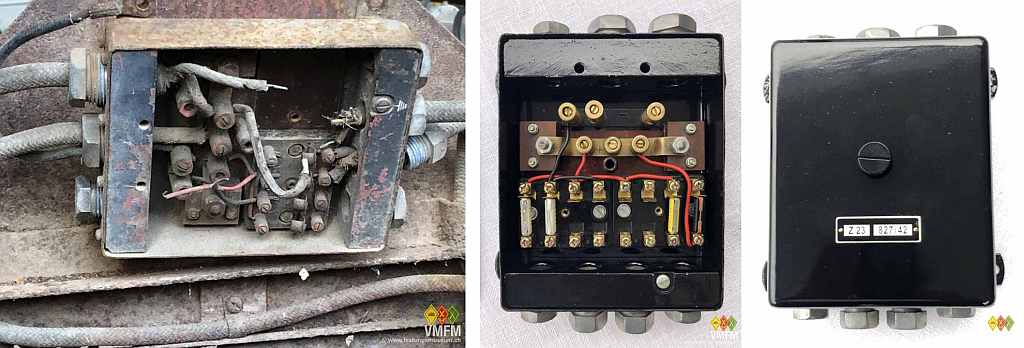

The restoration of the five electrical distributor boxes was a job for detail fanatics.

Kasten Pz. 5 c: entire power supply for the turret

Kasten Pz. 21 und 22: Intercom connections for commander (21) and gunner (22)

Kasten Z 23:

Small switch board: external power supply for loading and heating of the accumulators

Kasten Pz. 20: central distributor for the intercom system

The original electronic components of the intercom system will not work anymore, so in particular the Kasten pz. 20 was restored only optically. This is basically valid also for the distribution boxes 20, 21 and Z 23.Their interior, however, would still be ready to use.

The hull roof cover for the driver and radio operator is supported and fixed under the hull roof by a frame. Major sections of the parts which hold the gasket in place were corroded and needed to be renewed. The parts were CMC-reconstructed and welded. The old gasket has lost a great deal of its elasticity over the decades but it was still usable.

The highlight of last year was the visit of Mike and Dave from Santa Fé / New Mexico.

Many visitors of our museum, and in particular the fans of the King Tiger, have built the tank as a model, each one to his individual abilities in different scales and detailing. But Mike’s Tiger really takes the cake: A half scale model, powered by a gasoline engine and ready for combat (even if only airsoft-battles).

Ok, not all details are half scale. The weight of appr. 2.5 to, the power of 24 hp out of 725 ccm and the maximum speed of appr. 5 mph fall short of the original. But revel in all these details:

Overall length is 3.64 meters and turret height is 1.46 meter.

Gasoline fuel tank capacity: 5 US-gallons.

The hull consists of steel, the turret and cannon is made of aluminium.

The current transaxles are one-sped transaxles. Mike seeks to get stronger two-speed transaxles that should give a higher top speed and a low gear for heavy turning and climbing.

Targeting is by a targeting cam viewing with up to 50 x magnification on a screen and with separate gradient ranging marks for cannon and gun to come.

95 A alternator for two batteries, turret rotation by a 12-V-motor.

An invertor supplies 120 V for the air compressor to fire gun and cannon.

Two driving cameras for close in viewing of the terrain with a monitor between the legs of the driver.

Both cannon and machine gun fire with compressed air.

The cannon fires Nerf rockets with a range of up to 140 m.

The vehicle has a fire suppression system in the engine bay rated for gasoline fires.

The single crew member is an allrounder and sits with his eyes clear the top of the turret.

We wish Mike a good trip at all times … and happy hunting.